Initially formed as a cylinder, the knitted material is rolled to produce a lay flat sock which can vary in width from 6mm to 1000mm.

Initially formed as a cylinder, the knitted material is rolled to produce a lay flat sock which can vary in width from 6mm to 1000mm.

The material has interlocking asymmetrical loops of wire which can move relative to one another, allowing sideways and lengthways stretch. Because each loop is bent like a small spring this also provide high resilience.

2. Material Choices:

Any material that can be drawn or spun into filament form can be used to produce a knitted mesh structure for use in the manufacture of our products including:

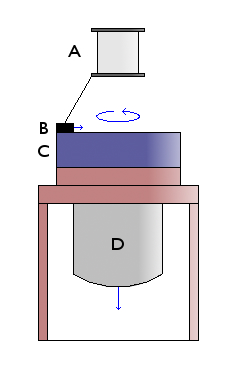

3.Knitting machines have four main points of interest:

A: The spool or spools of material to be knit

B: The filament/strand feeder

C: The cylinder head

D: The knit sock

Material strands are pulled from the feeder spools, channelled through the strand feeder, and knit by the needles held in the cylinder head. The knit material is then drawn through and stored for further processing.

Changing the number of feeder spools, strand feeders and set-up, and size, arrangement and number of needles in the cylinder head enables various types of mesh to be knit.

our factory has a huge range of knitting machines, cylinder heads, and strand feeder set-ups which allows them to make knitted mesh to almost any customer specification.

For more information on how we can satisfy your knitted mesh requirement, pls feel free to contact us.

4.Multi-Strand Knittingmeans to knit more than one strand or filament material into a mesh product.Hand-knitting and simple machine-knitting techniques mean a single strand or filament makes up the entire garment. By modifying cylinder feeders, spool positions and the materials used, KnitMesh is able to produce a vast array of multi-filament, co-knit, and multi-strand meshes. |

Figure 1. Single-loop mesh |

Multi-Filament MeshSimple machine-knit mesh has a single strand or filament in each knitted loop (as seen in Figure 1). Multi-filament mesh combines several strands of a similar material to form the loops (Figure 2). |

Co-Knit MeshCo-knit mesh is similar to multi-filament mesh, but this time different materials are combined into each knitted loop (Figure 3). |

Multi-Strand MeshMulti-strand mesh is similar to single-loop knitting, but in this case the knit layers are phased with different materials. Figure 4 shows a simple ABAB layering structure but more complex phasings are possible (ABAC... etc.) |

Multi-Layer MeshMesh is usually knit as a single sock but it is possible to knit one sock of mesh inside another (Figure 5). |

Figure 2. Multi-filament mesh |

Figure 3. Co-knit mesh |

Figure 4. Multi-strand mesh |

Figure 5. Multi-layer mesh |